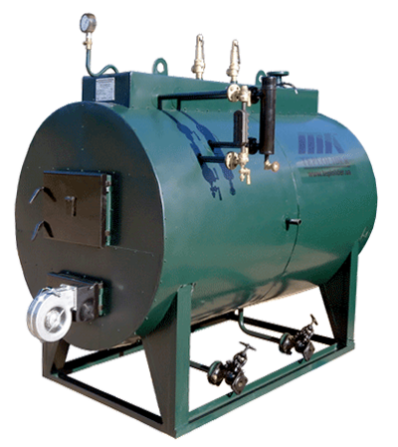

Steam boiler KP-300 on solid fuel

1 UAH

Steam boiler KP-300 on solid fuel

№1518 Created: 4 May 2022

Sell

Offer type:

Sell

Type of company activity:

Manufacture

Availability:

In stock

Country of origin:

Ukraine

Solid fuel boiler KP-300 has a steam capacity of up to 300 kilograms per hour. Coal, wood, straw, wood waste and agricultural enterprises can be used as fuel. Steam calving KP-300 is a horizontal cylindrical unit with a large furnace surrounded by a water jacket, a convective bundle of pipes behind the furnace, an ash collector at the bottom and a steam collector at the top. At the front of the boiler is a solid fuel loading hatch with a boost fan. To improve heat transfer, a combustion chamber is located behind the furnace, during the combustion of which all the thermal energy is transferred to the convective beam, which forms an additional jacket. Thus, there is a rapid heating of water and the formation of steam in the steam boiler. Steam with a pressure of up to 0.07 MPa is discharged from the boiler through the steam outlets. Flue gases are removed through the flue behind the boiler. The KP-300 steam boiler is made together with the boiler automation, which controls the whole process of steam production - air supply to the furnace, temperature and steam pressure. The KP-300 copper has metal support for fastening to the base in a boiler room.

№1518 Created: 4 May 2022